AW series for AW4000-04 Port size G1/2 Air Filter Pneumatic Regulator

Ukunaka Ukukhetha

1. Ungasikhetha kanjani isihlungi ngokwenani lokugeleza?

Khetha izinga lokugeleza elifanele ngokuya ngokusetshenziswa komoya kwemishini ephansi komfula. Ngokuvamile, sikhetha isihlungi esikhulu kancane kunokusetshenziswa komoya kwangempela ukuze sigweme umthamo womoya onganele futhi sithinte ukusebenza kwemishini.Asikho isidingo sokukhetha isihlungi esinezinga lokugeleza ngokweqile, elizodala imfucuza. (Bheka ithebula lokugeleza elingezansi ukuthola ukugeleza okuthile komkhiqizo)

| Imodeli yeprosesa yomthombo womoya | Intambo yesixhumi esibonakalayo | Ukugeleza |

| AC2000/AFC2000 | 1/4 =2″ | 500L/min |

| I-AR/AFR/AF/AL2000 | 1/4 =2″ | 500L/min |

| BC/BFC/BF/BR/BFR/BL2000 | 1/4 =2″ | 2000L/min |

| BC/BFC/BF/BR/BFR/BL3000 | 3/8=3″ | 3000L/min |

| BC/BFC/BF/BR/BFR/BL4000 | 1/2=4″ | 4000L/min |

2. Ungakhetha kanjani ukunemba kwesihlungi sesici sokuhlunga?

Ububanzi bembotshana besici sokuhlunga sesihlungi sinquma ukunemba kokuhlunga kwesihlungi. Ngoba imishini engezansi inezidingo ezahlukene zekhwalithi yomthombo wegesi. Isibonelo, i-metallurgy, insimbi nezinye izimboni azinazo izidingo eziphezulu zekhwalithi yegesi, ngakho-ke ungakhetha isihlungi esinosayizi omkhulu wembotshana yesihlungi. Kodwa-ke, izimboni ezifana nemithi kanye ne-electronics zinezidingo eziphezulu zekhwalithi yegesi. Singakhetha izihlungi ezinembayo ezinezimbotshana zokuhlunga ezincane kakhulu.

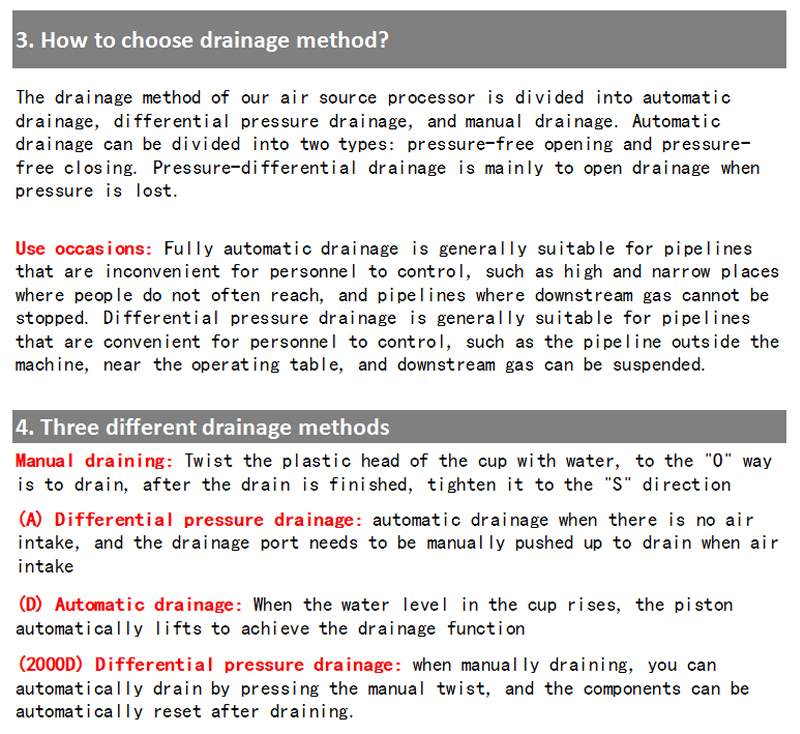

3. Indlela yokukhetha indlela yokukhipha amanzi?

Indlela yokukhipha amanzi yeprosesa yethu yomthombo womoya ihlukaniswe yaba i-drainage ezenzakalelayo, i-drainage pressure drainage, kanye ne-drainage eyenziwa ngesandla. I-automatic drainage ingahlukaniswa ngezinhlobo ezimbili: ukuvula okungacindezeli kanye nokuvala okungenasici. I-drainage-mehluko we-pressure ikakhulukazi ukuvula i-drainage lapho kulahleka ingcindezi.

Izikhathi zokusebenzisa: Ukugeleza kwamanzi okuzenzakalelayo ngokugcwele ngokuvamile kulungele amapayipi okungafanelekile ukuthi izisebenzi ziwalawule, njengezindawo eziphakeme neziwumngcingo lapho abantu bengavamisile ukufinyelela khona, namapayipi lapho igesi engaphansi komfula ingenakuvinjwa. Amapayipi okucindezela okuhlukile ngokuvamile afanele amapayipi alungele izisebenzi ukuwalawula, njengepayipi elingaphandle komshini, eduze kwetafula lokusebenza, kanye negesi engezansi ingamiswa.

4. Izindlela ezintathu ezahlukene zokudonsa amanzi

Ukudonsa ngesandla: Sonta ikhanda lepulasitiki lenkomishi ngamanzi, uye ku-"0", indlela yokukhipha amanzi, ngemva kokuqedwa kokukhishwa, qinisa ku-"S"

(A) I-differential pressure drainage: ukudonsa amanzi okuzenzakalelayo lapho umoya ungangeni, futhi imbobo yokukhipha amanzi idinga ukuphushwa ngesandla ukuze ikhiphe lapho kungena umoya.

(D) I-Automatic drainage: Lapho izinga lamanzi enkomishini likhuphuka, i-piston iphakamisa ngokuzenzakalelayo ukuze kuzuzwe umsebenzi wokudonsa amanzi.

(2000D) I-Differential pressure drainage: lapho udonsa ngesandla, ungakhipha ngokuzenzakalelayo ngokucindezela i-twist manual, futhi izingxenye zingasethwa kabusha ngokuzenzakalelayo ngemva kokukhipha amanzi.

Ukucaciswa

| Ingcindezi yobufakazi | 1.5Mpa{15.3kgf/cm²} |

| Ubukhulu. ingcindezi yokusebenza | 1.0Mpa(10.2kgf/cm²} |

| Imvelo kanye nokushisa kwamanzi | 5 ~ 60℃ |

| Indawo yokuhlunga | 5mm |

| Phakamisa amafutha | SOVG32 Turbine 1 amafutha |

| Izinto zenkomishi | I-Polycarbonate |

| Isigqoko sendebe | AC1000~2000 ngaphandleAC3000~5000 nge(lron) |

| Ibanga lokulawula ingcindezi | AC1000:0.05-0.7Mpa(0.51-7.1kgf/cm²)AC2000~5000:0.05~0.85Mpa(0.51~8.7kgf/cm²) |

Qaphela: kukhona 2,10,20,40,70.100μm ongakhetha

| Imodeli | Ukucaciswa | ||||

| Ukugeleza okuncane kokusebenza | Ukugeleza okulinganiselwe(L/min) | Usayizi wetheku | Umthamo wendebe | Isisindo | |

| I-AC1000-M5 | 4 | 95 | M5x0.8 | 7 | 0.07 |

| AC2000-02 | 15 | 800 | 1/4 | 25 | 0.22 |

| AC3000-02 | 30 | 1700 | 1/4 | 50 | 0.30 |

| AC3000-03 | 40 | 5000 | 3/8 | 50 | 0.30 |

| AC4000-03 | 40 | 5000 | 3/8 | 130 | 0.56 |

| AC4000-04 | 50 | 5000 | 1/2 | 130 | 0.56 |

| AC4000-06 | 50 | 6300 | 3/4 | 130 | 0.58 |

| AC5000-06 | 190 | 7000 | 3/4 | 130 | 1.08 |

| AC5000-10 | 190 | 7000 | 1 | 130 | 1.08 |

Ukwelashwa Komthombo Womoya kuhilela uchungechunge lwemisebenzi esiza ukukhiqiza umoya ocindezelweyo ohlanzekile, owomile futhi ongenawo ukungcola. Ngokuvamile, isistimu ihlanganisa izihlungi, okomisa, izihlukanisi, nezinye izakhi ezibalulekile ezisebenza ndawonye ukuqeda noma yiziphi izakhi eziyingozi emoyeni ocindezelweyo. Esinye isici esibalulekile sokwelashwa ukususwa komswakama ngokweqile, okungabangela ukugqwala ohlelweni lomoya.